|

|

|

| |

| 能谱分析标样 |

|

UHV-EL Reference Standards

for EDS/WDS

Ultra High Vacuum Compatible

Micro and Macro Analysis

Standard for Surface and X-ray Analysis

- UHV (ultrahigh vacuum) compatible (10 -10 torr)

- Suitable for spectral and intensity references in the following spectroscopies:

EDS, WDS, EPMA, Auger, XPS, ESCA, etc.

- Custom and standard reference material (RMs) configurations

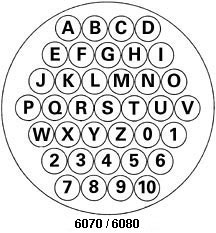

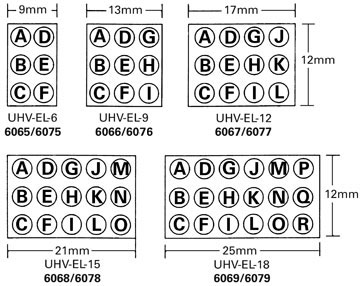

- Rectangular or circular retainers holding from 6 to 37 RMs

- Retainers machined from SS304

- Custom mounting bases available

- Each RM is individually and separately:

prepared from bulk or powdered materials, polished with the most suitable method, and can easily be removed or reinserted into the retainer

Analysis accuracies of 1-2% (relative) are possible only when appropriate standards are used. UHV systems cannot accept commonly available standard sets because of outgassing of mount materials and degradation from electron beam heating. The use of bakelite, plastic or epoxy embedded standards under UHV conditions have prevented accurate analysis. These inaccuracies are caused by compromised vacuum levels and contaminated RMs. Also, standardless techniques give no indication that some elements may not be accounted for or are present in an oxide phase.

RMs supplied with the UHV-EL, which contain only UHV compatible materials, can be used to characterize the transmission of the electron energy analyzer, determine peak shapes, resolution, energies and sensitivity factors.

|

Since generalized sensitivity factors cannot be used with a reasonable degree of accuracy, even for the same instrument model, it is necessary for these factors to be determined for each unique instrument, on a continuing basis. Conditions will change over time because of peak shift, amplifier settings and spectrometer tolerances.

Design

The retainer is precision machined by numerically controlled tools from stainless steel 304. The round UHV-EL-37 is laser engraved to assist in locating the desired RM using electron or optical imaging. All RMs are precisely referenced within 0.13mm of the top surface. This recess protects the RM surfaces from contamination and scratching and also minimizes the possibility of X-ray fluorescence from the retainer. The RMs, which are of various thicknesses, are retained by SS304 clips which are inserted from the bottom of the mount.

RMs are individually sized and polished according to the properties of the material. Cross contamination and smearing is avoided. Each RM is a full 3mm in diameter and the entire surface is usable.

If an RM surface gets roughened from excessive ion beam sputtering or is too highly oxidized, it can be easily removed and replaced in your laboratory. Tools and clips are provided. If bulk materials are not available for some RM, powders are used. They are consolidated with silver flake and the powder grains metallographically polished. Many insulators prepared this way are sufficiently conductive for X-ray and Auger analysis without carbon coating. The silver can be used for reference when determining sensitivity factors.

Custom Preparation

Your materials may be inserted into one of the retainers described using careful techniques. For electron beam X-ray techniques, RMs, which are charge sensitive, can be carbon coated.

Shipping

UHV-EL-37 circular retainer reference standards are shipped in a VACU-STORR container. It is optional for other configurations or custom orders.

|

Retainers

For Configuration, designate Retainer Style and Element/Compound locations and numbers:

Use the submit form

or print out the PDF form and fill in the numbers in the actual spaces for the desired elements/compounds and fax it to us at: 530-243-3761.

See below for a list of elements and compounds and their respective order numbers. |

25mm diameter

|

|

Prod #

|

Description

|

Unit

|

Price

|

|

UHV-EL Retainers Without Standards

|

|

6065

|

UHV-EL Rectangular Retainer Standard, 8.5 x 12.5mm, 6 spaces

|

each

|

|

|

6066

|

UHV-EL Square Retainer Standard, 12.5 x 12.5mm, 9 spaces

|

each

|

|

|

6067

|

UHV-EL Rectangular Retainer Standard, 16.5 x 12.5mm, 12 spaces

|

each

|

|

|

6068

|

UHV-EL Rectangular Retainer Standard, 19.5 x 12.5mm, 15 spaces

|

each

|

|

|

6069

|

UHV-EL Rectangular Retainer Standard, 24 x 12.5mm, 18 spaces

|

each

|

|

|

6070

|

UHV-EL Round Retainer, 25mm diameter, 37 spaces

|

each

|

|

|

UHV-EL Single Element Standards (3mm dia.) for Retainers

|

|

6060

|

UHV-EL - Any Single Standard other than Diamond, Cu/Au or Al/Cu (specify number from list)

|

each

|

|

|

6061

|

Diamond UHV-EL Single Standard, (No. 168 on list)

|

each

|

|

|

6062

|

Cu/Au UHV-EL Single Standard, SRM482, 5 wires (No. 197 on list)

|

each

|

|

|

6063

|

Al/Cu UHV-EL Single Standard (No. 230 on list)

|

each

|

|

|

6064

|

Faraday Cup for UHV-EL to measure beam current

|

each

|

|

|

UHV-EL Retainers Complete With Standards

|

|

6075

|

UHV-EL Rectangular Retainer Standard, 8.5 x 12.5mm, 6 elements

|

each

|

|

|

6076

|

UHV-EL Square Retainer Standard, 12.5 x 12.5mm, 9 elements

|

each

|

|

|

6077

|

UHV-EL Rectangular Retainer Standard, 16.5 x 12.5mm, 12 elements

|

each

|

|

|

6078

|

UHV-EL Rectangular Retainer Standard, 19.5 x 12.5mm, 15 elements

|

each

|

|

|

6079

|

UHV-EL Rectangular Retainer Standard, 24 x 12.5mm, 18 elements

|

each

|

|

|

6080

|

UHV-EL Round Retainer, 25mm diameter, 37 elements

|

each

|

|

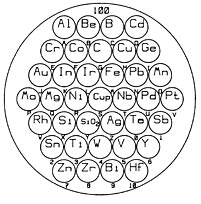

Standard Round Retainer

Configuration |

Round Retainers can be ordered Standard or Custom

Ordering the round UHV-EL Retainer requires that Standard or Custom be chosen. The Standard selection is shown to left. A custom order requires that details be given regarding the elements chosen and the configuration (a "blank" Custom Round Retainer is shown for ordering - please print out and fill in exactly as needed).

|

Note: For Custom Configuration designate Element/Compound locations and numbers: Use the submit form

or print out the PDF form and fill in the numbers in the actual spaces for the desired elements/compounds and fax it to us at: 530-243-3761.

See below for a list of elements and compounds, preceded by their respective order numbers.

Element Standards for RMs

| |

Abbreviations

| M |

natural mineral |

| Opt |

optical crystal |

| P |

powder: mixed with either Ag or Sn (for S containing materials) |

| TF |

thin film on silicon wafer |

| VD |

vapor deposit (CVD, LPCVD, etc.) |

| B |

bulk material |

| C |

crystalline |

| EM |

end member mineral |

| F |

foil |

| HP |

hot pressed |

| "+" |

higher purity |

| *Purity |

"N" is the # of "9"'s. 5N would be 99.999% pure, 2N5 would be 99.5% |

|

| Element/Compound |

Symbol |

Form |

Purity |

|

Element/Compound |

Symbol |

Form |

Purity |

1. Aluminum

2. Aluminum Fluoride

3. Aluminum Oxide

4. Aluminum Nitride

5. Antimony

6. Barium Fluoride

7. Barrium Sulfate

8. Barium Titanate

9. Barium Titanate

10. Beryllium

11. Bismuth

12. Bismuth Oxide

13. Boron

14. Boron Carbide

15. Boron Nitride

16. Boron Phosphide

17. Cadmium

17A. Cadmium Sulfide

18. Calcium Carbonate

19. Calcium Fluoride

20. Carbon (Pyrolytic)

21. Carbon (Diamond)

22. Cerium Oxide

23. Cesium Iodide

24. Chromium

24A. Chromium Carbide

25. Chromium Nitride

26. Chromium Oxide

27. Cobalt

28. Cobalt Oxide

29. Cobalt Silicide

30. Copper

31. Cupric Oxide

32. Cuprous Oxide

33. Copper Sulfide

34. Copper Sulfide

35. Dysprosium

36. Erbium

38. Gadolinium

39. Gallium Arsenide

40. Gallium Nitride

41. Gallium Phosphide

42. Gallium Antimonide

43. Germanium

44. Germanium Oxide

45. Gold

46. Hafnium

46A. Hafnium Boride

47. Hafnium Carbide

47A. Hafnium Nitride

47B. Hafnium Oxide

48. Holmium

49. Indium

50. Indium Arsenide

51. Indium Phosphide

52. Indium Antimonide

52A. Indium Tin Oxide

53. Iridium

54. Iron

55. Iron Fluoride

56. Iron Fluoride

57. Iron Nitride

58. Iron Oxide

59. Iron Oxide

60. Iron Oxide

61. Iron Phosphide

62. Iron Sulfide

63. Lead

64. Lead Oxide

65. Lead Sulfide

66. Lanthanum Hexaboride

68. Lithium Fluoride

69. Magnesium

70. Magnesium Fluoride

71. Magnesium Oxide

72. Manganese

73. Manganese Sulfide

74. Manganese Oxide

75. Mercury Sulfide

76. Molybdenum |

Al

AlF3

Al2O3

AlN

Sb

BaF2

BaSO4

BaTi4O9

BaTiO3

Be

Bi

Bi2O3

B

B4C

BN

BP

Cd

CdS

CaCO3

CaF2

C

C

CeO2

CsI

Cr

Cr3C2

Cr2N

Cr2O3

Co

Co3O4

CoSi2

Cu

CuO

Cu2O

CuS

Cu2S

Dy

ER

Gd

GaAs

GaN

GaP

GaSb

Ge

GeO

Au

Hf

HfB2

HfC

HfN

HfO2

Ho

In

InAs

InP

InSb

5% In

Ir

Fe

FeF2

FeF3

Fe3N

FeO

Fe2O3

Fe3O4

FeP

FeS2

Pb

PbO

PbS

LaB6

LiF

Mg

MgF2

MgO

Mn

MnS

MnO2

HgS

Mo |

F

P

C

P

B

C

P

HP

P

F

B

P

P

P

B

P

F

P

C

C

CVD

C

P

O

P

P

P

HP

F

P

P

F

P

EM

M

M

F

F

F

C

P

P

P

B

P

F

F

P

B

P

P

B

F

C

C

P

F

F

F

P

P

P

P

EM

EM

P

P

F

P

P

C

C

F

C

C

B

P

TF

C

F |

3N

4N

3N

2N5

4N

2N+

2N

2N

3N

2N5

5N

3N

2N8

2N

2N5

1N75

5N

4N

3N

Opt

3N

3N+

3N

5N

4N7

2N5

2N

2N7

4N6

2N5

2N5

5N

5N

3N

2N

2N

3N

3N

3N

2N+

4N

5N

4N

5N

5N

3N

2N5

2N5

2N

2N5

3N

3N

4N7

6N

3N

5N

3N

3N

5N

3N

3N

3N

3N

3N

3N

2N5

3N

5N

5N

3N

3N

Opt

2N8

Opt

3N5

3N

3N

3N

4N

3N

|

|

77. Molybdenum Carbide

78. Molybdenum Silicide

79. Molybdenum Oxide

81. Osmium

81A. Neodymium Fluoride

82. Nickel

83. Nickel Oxide

84. Nickel Phosphide

85. Nickel Silicide

86. Niobium

87. Niobium Carbide

88. Niobium Oxide

89. Palladium

90. Platinum

91. Potassium Bromide

92. Potassium Chloride

93. Potassium Iodide

94. Rhenium

95. Rhenium Oxide

96. Rhodium

97. Rubidium Chloride

98. Ruthenium

99. Samarium

100. Scandium

101. Selenium

102. Silicon

103. Silicon Carbide

104. Silicon Dioxide

105. 1000Å/Silicon

106. Silicon Nitride

107. 468Å/Silicon

108. Silver

109. Silver Chloride

110. Silver Sulfide

111. Sodium Chloride

112. Sodium Fluoride

113. Strontium Fluoride

114. Tantalum

115. Tantalum Carbide

116. Tantalum Nitride

117. Tantalum Oxide

118. Tantalum Oxide

119. 1000Å/Ta

120. Tantalum Silicide

121. Tellurium

122. Terbium

123. Thallium Chloride

124. Thorium Oxide

125. Thulium

126. Tin

127. Tin Oxide

128. Titanium

129. Titanium Carbide

130. Titanium Diboride

131. Titanium Dioxide

132. Titanium Nitride

133. Titanium Silicide

134. Tungsten

135. Tungsten Carbide

136. Tungsten Nitride

137. Tungsten Oxide

138. Tungsten Silicide

139. Uranium 238

---Note: partially oxidized

140. Vanadium

141. Vanadium Carbide

141A. Vandium Nitride

142. Vanadium Oxide

142A. Ytterblum

143. Yttrium

144. Yttrium Oxide

145. Zinc

146. Zinc Oxide

147. Zinc Selenide

148. Zinc Sulfide

149. Zirconium

150. Zirconium Carbide

150A. Zirconium Nitride

151. Zirconium Oxide |

Mo2C

MoSi2

MoO3

Os

NdF2

Ni

NiO

Ni2P

NiSi2

Nb

NbC

Nb2O5

Pd

Pt

KBr

KCl

KI

Re

ReO3

Rh

RbCl

Ru

Sm

Sc

Se

Si

SiC

SiO2

SiO2

Si3N4

Si3N4

Ag

AgCl

Ag2S

NaCl

NaF

SrF2

Ta

TaC

TaN

Ta2O5

Ta2O5

TaSi2

Te

Tb

TlCl

ThO2

Tm

Sn

SnO2

Ti

TiC

TiB2

TiO2

TiN

TiSi2

W

WC

WN

WO3

WSi2

U

V

VC

VN

V2O5

Yb

Y

Y2O3

Zn

ZnO

ZnSe

ZnS

Zr

ZrC

ZrN

ZrO2

|

HP

P

P

P

C

F

P

P

P

F

HP

P

F

F

C

C

C

F

P

F

P

P

F

F

C

C

CVD

EM

TF

HP

TF

F

C

C

C

C

P

F

HP

P

P

TF

P

B

F

P

P

F

F

EM

F

HP

HP

EM

P

P

F

HP

P

P

P

F

F

HP

HP

P

F

F

P

F

HP

C

C

F

HP

P

C

|

2N5

2N+

2N5

4N5

4N

4N8

3N

2N5

2N

2N8

2N5

3N5

3N

3N

Opt

Opt

Opt

4N

3N

4N

4N

3N5

3N

3N8

2N+

3N

3N

3N

2N7

1N8

4N8

3N

3N

Opt

Opt

2N5

3N5

2N

2N5

3N5

2N5

5N

3N

5N

3N

3N

4N8

1N8

2N8

2N5

2N5

2N

2N5

2N5

3N8

2N5

2N5

2N5

2N5

2N7

2N5

2N5

2N5

4N5

3N

3N

4N

4N8

3N

2N+

Opt

4N

2N5

2N5

4N

|

| Mineral |

Formula (approximate) |

|

Mineral |

Formula (approximate) |

152. Acanthite

152. Albite

154. Almandine

155. Andradite

156. Anorthite

157. Barite

158. Benitoite

159. Biotite (black mica)

160. Bytownite

161. Calcium Caronate

162. Cassiterite

163. Chalcocite

164. Cinnabar

165. Chrysoberyl

166. Covellite

167. Cuprite

168. Diamond (additional cost) |

Ag2S

NaAlSi3O8

Fe3+2Al2(SiO4)3

Ca3Fe2+3(SiO4)3

CaAl2Si2O8

BaSO4

BaTiSi3O9

K(Mg,Fe+2)3(Al,Fe+3)Si3O10(OH,F)2

(Na, Ca)Al(Al,Si)Si2O8

CaCO3

SnO2

Cu2S

HgS

BeAl2O4

CuS

Cu2O

C (cleaved ~1mm) |

|

169. Diopside

170. Dolomite

170A. Fayalite

171. Fluorapatite

172. Forsterite

173. Hematite

174. Hornblende

(Amphibole)

175. Kyanite

176. Magnetite

177. Orthoclase

178. Quartz

179. Rutile

180. Sodalite

181. Spinel

182. Willemite (Troosite)

183. Wollastonite |

CaMgSi2O6

CaMg(CO3)2

Fe2 2+SiO4

Ca5(PO4)3F

Mg2SiO4

Fe2O3

Ca2(Mg,Fe+2)4Al(Si7Al)O22(OH,F)2

Al2O3.SiO2

Fe3O4

K2O.Al2O3.6SiO2

SiO2

TiO2

Na4(AlCl)Al2(SiO4)3

MgAl2O4

Zn2SiO4

CaSiO3 |

Note: electron probe compositions provided upon request or with standard.

| SRM# National Institute of Standards & Technology (formerly NBS) Please see note below regarding alloys. |

| Glasses |

B2O3 |

Na2O |

MgO |

Al2O3 |

SiO2 |

Cl |

K2O |

CaO |

TiO2 |

V2O5 |

Cr2O3 |

MnO2 |

Fe2O3 |

ZrO2 |

PbO |

Bi2O3 |

BaO |

ZnO |

CoO |

CuO |

| 184. 612 |

|

14.0 |

|

2.0 |

72.0 |

|

|

12.0 |

|

+50 ppm of 51 other elements |

|

|

|

|

|

|

|

| 185. 93a |

12.5 |

3.9 |

|

2.2 |

80.8 |

.06 |

.01 |

.01 |

.01 |

|

|

|

.028 |

.04 |

|

|

|

|

|

|

| 186. K252 |

|

|

|

|

40.0 |

|

|

|

|

|

|

5.0 |

|

|

|

|

35.0 |

10.0 |

5.0 |

5.0 |

| 187. K229 |

|

|

|

|

30.0 |

|

|

|

|

|

|

|

|

|

70.0 |

|

|

|

|

|

| 188. K326 |

30.0 |

2.0 |

30.1 |

|

29.9 |

|

|

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

| 189. K309 |

|

|

|

15.0 |

40.0 |

|

|

15.0 |

|

|

|

|

15.0 |

|

|

|

15.0 |

|

|

|

| Ti Alloys |

Fe |

C |

Mn |

P |

S |

Si |

Cu |

Zn |

Pb |

Sn |

Ni |

Cr |

V |

Mo |

Ti |

As |

W |

Zr |

Nb |

Ta |

Al |

Co |

| 190. 654b |

.23 |

|

|

|

|

.045 |

.004 |

|

|

.023 |

.028 |

.025 |

4.31 |

.013 |

88.05 |

|

|

.008 |

|

|

6.34 |

|

| 191. 1128 |

.134 |

.011 |

|

|

|

|

|

|

|

3.04 |

|

2.96 |

15.13 |

|

75.64 |

|

|

|

|

|

3.06 |

|

| Miscellaneous NIST Standards |

| 192. 1104 |

.088 |

|

|

.005 |

|

|

61.33 |

35.31 |

2.77 |

.43 |

.07 |

|

|

|

|

|

|

|

|

|

|

|

| 193. 1108 |

.044 |

|

.0025 |

|

|

|

64.9 |

34.4 |

0.06 |

.39 |

.033 |

|

|

|

|

|

|

|

|

|

|

|

| 194. 1110 |

.033 |

|

|

|

|

|

84.5 |

15.2 |

0.03 |

.051 |

.053 |

|

|

|

|

|

|

|

|

|

|

|

| 195. 1230 |

Bal |

.044 |

.64 |

.023 |

.0007 |

.43 |

.14 |

|

|

|

2.42 |

14.8 |

.23 |

1.18 |

2.12 |

|

|

|

|

|

.24 |

.15 |

| 195A. 1243 |

.79 |

.024 |

.019 |

.003 |

.0018 |

.018 |

.007 |

|

|

|

58.78 |

19.20 |

.12 |

4.25 |

3.06 |

|

|

.053 |

|

|

1.23 |

12.46 |

| 196. C2402 |

7.3 |

.01 |

.64 |

.007 |

.018 |

.85 |

.19 |

|

|

|

51.5 |

16.15 |

.22 |

17.1 |

|

|

4.29 |

|

|

|

|

1.5 |

| 197. SRM-482 5 wires in one 3mm f mount. Cu:Au (20:80, 40:60, 60:40, 80:20) + pure Cu (additional cost) |

| Steels |

Fe |

C |

Mn |

P |

S |

Si |

Cu |

Zn |

Pb |

Sn |

Ni |

Cr |

V |

Mo |

Ti |

As |

W |

Zr |

Nb |

Ta |

Al |

Co |

| 198. 461 |

Bal |

.15 |

.36 |

.053 |

.019 |

.047 |

.34 |

|

.003 |

.022 |

1.73 |

.13 |

.024 |

.3 |

.01 |

.028 |

.01 |

<.005 |

.011 |

.002 |

.005 |

.26 |

| 199. 462 |

Bal |

.40 |

.94 |

.045 |

.019 |

.28 |

.20 |

|

.006 |

.066 |

.70 |

.74 |

.058 |

.08 |

.037 |

.046 |

.053 |

.063 |

.096 |

.036 |

.02 |

.10 |

| 200. 464 |

Bal |

.54 |

1.32 |

.017 |

.021 |

.48 |

.094 |

|

.02 |

.043 |

.13 |

.078 |

.29 |

.029 |

.004 |

.018 |

.022 |

.01 |

.037 |

.069 |

.005 |

.02 |

| 201. 465 |

Bal |

.037 |

.032 |

.008 |

.01 |

.029 |

.019 |

|

<.0005 |

.001 |

.026 |

.004 |

.002 |

.005 |

.20 |

.01 |

.001 |

.002 |

.001 |

.001 |

.19 |

.08 |

| 202. 466 |

Bal |

.065 |

.11 |

.012 |

.009 |

.025 |

.033 |

|

.001 |

.005 |

.051 |

.011 |

.007 |

.011 |

.057 |

.014 |

.006 |

<.005 |

.005 |

.002 |

.01 |

.04 |

| 203. 467 |

Bal |

.11 |

.23 |

.003 |

.009 |

.26 |

.067 |

|

.000 |

.1 |

.088 |

.036 |

.041 |

.021 |

.26 |

.14 |

.20 |

.094 |

.29 |

.23 |

.16 |

.07 |

| 204. 468 |

Bal |

.26 |

.47 |

.023 |

.02 |

.075 |

.26 |

|

<.0005 |

.009 |

1.03 |

.54 |

.17 |

.20 |

.011 |

.008 |

.077 |

<.005 |

.006 |

.005 |

.04 |

.16 |

| 205. 661 |

Bal |

.39 |

.66 |

.015 |

.015 |

.223 |

.042 |

|

|

.01 |

1.99 |

.69 |

.011 |

.19 |

.02 |

.017 |

.01 |

.009 |

.22 |

.02 |

.02 |

.03 |

| 206. 663 |

Bal |

.57 |

1.50 |

.02 |

.005 |

.74 |

.09 |

|

.0022 |

|

.32 |

1.31 |

.31 |

.30 |

.05 |

.01 |

.04 |

.05 |

.049 |

|

.24 |

.05 |

| 207. 664 |

Bal |

.87 |

.25 |

.01 |

.025 |

.066 |

.25 |

|

.024 |

|

.14 |

.06 |

.10 |

.49 |

.23 |

.05 |

.10 |

.069 |

.15 |

.11 |

|

.15 |

| 208. 665 |

Bal |

.008 |

.0057 |

.002 |

.0059 |

.008 |

.0058 |

|

|

|

.041 |

.007 |

.0006 |

.005 |

.0006 |

.002 |

|

|

|

|

|

.01 |

| 209. 1761 |

Bal |

1.03 |

.68 |

.043 |

.033 |

.19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 210. 1762 |

Bal |

.034 |

2.03 |

.036 |

.03 |

.36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 211. 1763 |

Bal |

.20 |

1.59 |

.012 |

.022 |

.65 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 212. 1764 |

Bal |

.59 |

1.22 |

.023 |

.012 |

.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 213. 1765 |

Bal |

.006 |

.14 |

.007 |

.004 |

.005 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 214. 1766 |

Bal |

.015 |

.06 |

.004 |

.002 |

.01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 215. 1767 |

Bal |

.051 |

.02 |

.005 |

.009 |

.02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 216. 1768 |

Bal |

.001 |

.014 |

.0013 |

.0003 |

|

.0006 |

|

|

|

.0014 |

|

|

|

|

|

|

|

|

|

.002 |

.002 |

| Alloys- Certified by a group of laboratories, NIST traceable. Analysis provided with each alloy purchased. |

| Stainless Steels |

Low Alloy |

Nickel/Cobalt |

Copper/Brass/Bronze |

+ High Temperature

217. AISI 303

218. AISI 304

219. AISI 316

220. AISI 321

221. AISI 410

222. AISI 440C

223. PH13-8MO

224. 15-5 PH

225. 17-4PH

226. CARP 20CB3

227. Maraging 300

228. HK-40 |

+ Specialty

233. C-4140

234. C-4340

235. C-8620

236. Tool Steel A-6

237. Tool Steel D-2

238. Tool Steel H-13

239. Tool Steel M-2

240. 2-Cr-lMo (36a)

241. 9-Cr-lMo (38a) |

242. Inco 600

243. Inco 625

244. Inco 718

245. Inco 800

246. Hastelloy C-22

247. Hastelloy C-276

248. Hastelloy X |

249. CDA 360

250. CDA 510

251. CDA 655

252. CDA 857 |

Miscellaneous Standards:

229. BPSG (not a NIST standard), 4% P, 3.3% B.

230. Al-Cu: NIST traceable standard for energy dispersive x-ray detector calibration (additional cost).

231. C-Cu-Ag: Standard for electron backscattering adjustment. Used for gun shot residue calibration

232. GSR- Gun shot residue: mixture of Ba, Sb, Pb particles in epoxy and carbon coated. |

| Faraday Cup, for beam current measurement, is available for all of the retainers and will take one of the spaces. |

PLEASE READ CAREFULLY!

The metal alloys on this list cannot be assumed to be homogenous at the micrometer scale. If you intend to use ZAF corrections electron beam excited x-ray analysis (wavelength or energy dispersive) the sample volume must be homogenous within the electron excited volume. It is a misuse to use these metal alloys for bulk quantitative analyses. Nevertheless, they are useful for comparison purposes (in a least square sense) to compare against unknown materials. Every effort is made to insure that cutting, grinding, and polishing of the materials do not alter their composition.

If you do not see a standard on the list that you would like, please contact us for availability. We can also prepare your materials for our mounts. |

|

|

|

|